This year, the Agricultural Technology Research Program (ATRP) is celebrating 50 years of service to Georgia agribusiness, especially the poultry industry. For five decades, ATRP has been proud to support the growing needs of Georgia’s dynamic poultry industry. With funding from the State of Georgia and in cooperation with the Georgia Poultry Federation, ATRP has been a driving force in developing new technologies that enhance the industry’s productivity and efficiency, and is recognized as one of the best university-based engineering R&D programs focused on the poultry industry. In addition to seeking solutions to today’s challenges, the program concentrates on transformational innovations that are essential for a viable industry in the future.

ATRP was initiated in 1973 when the Georgia Poultry Federation asked the Georgia General Assembly for $100,000 to involve the Georgia Tech Engineering Experiment Station (now the Georgia Tech Research Institute) in studies to support the poultry industry. The first research project tackled a noise-abatement problem in poultry processing plants.

Snapshot of ATRP

Investment

ATRP has grown into a multi-million dollar program with an annual ROI of

$2.5M*

*as of FY 2022

Innovation

20 50+

Patents Records of Invention

Community

30+

Technical Assistance Service Requests Fulfilled Annually

Education

100s

of undergraduate/graduate students trained, including the R. Harold and Patsy Harrison Student Interns in the Abit Massey Student Internship Program

Outreach

Award-winning PoultryTech newsletter and participation in industry tradeshows and conferences

Collaboration

60+

Industry and Academic Partners

Row Crops Research Initiative

Row Crops Research Initiative

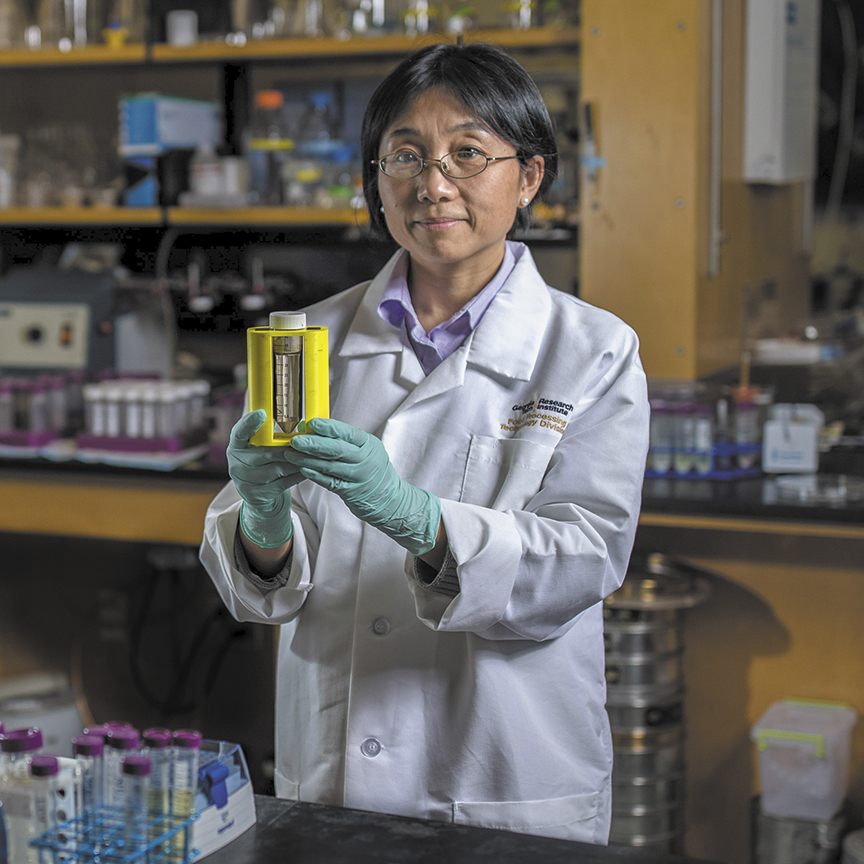

To further serve Georgia’s agriculture sector, ATRP recently began a Row Crops Research Initiative focused on using volatile organic compounds (VOCs) for aflatoxin detection in peanuts.

(text and background only visible when logged in)

Five Decades of Driving Transformational Innovation

With a strong commitment to engineering excellence and industry service, ATRP researchers have found innovative answers to ongoing challenges and developed new technologies that have improved industrial productivity and efficiency. A sampling of successful innovations includes…

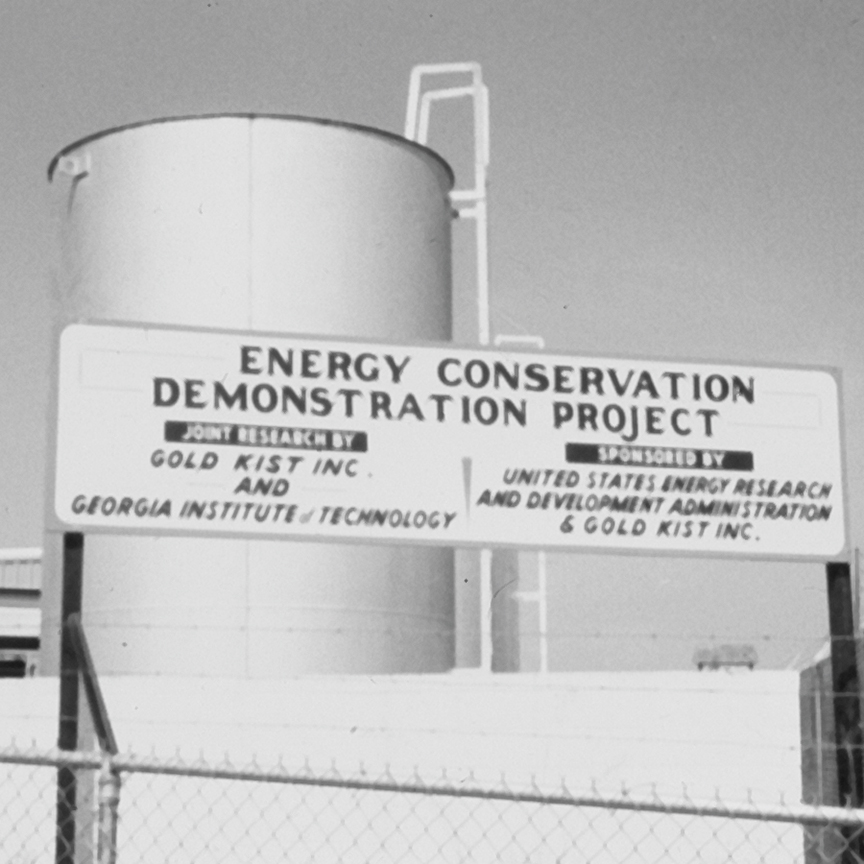

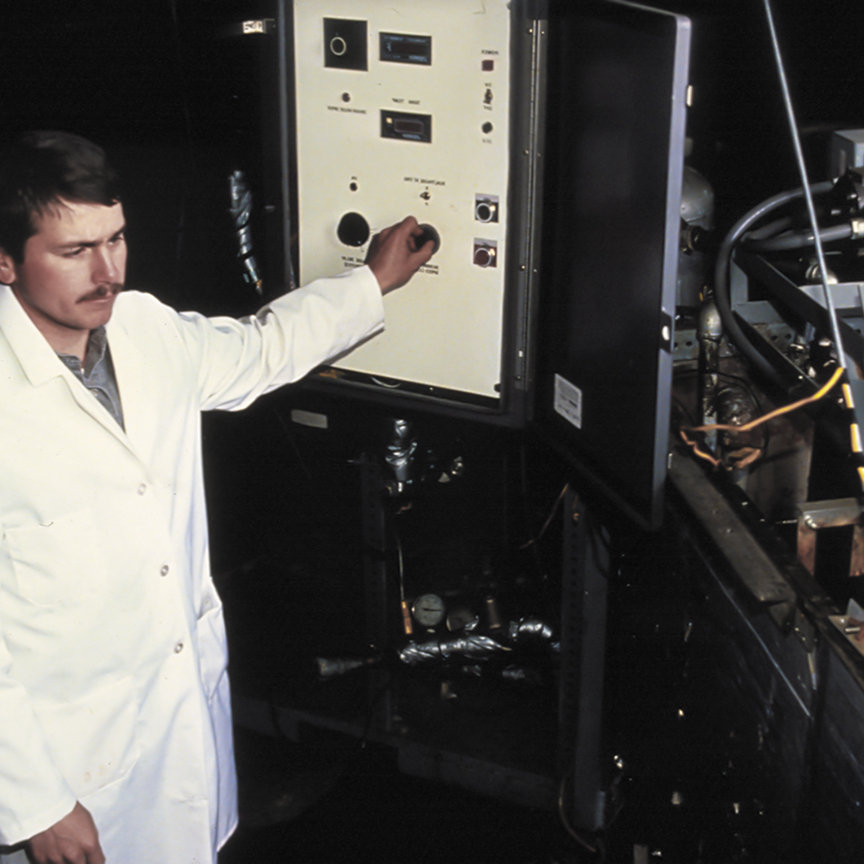

1970s – Demonstration Projects

During the 1970s, with the country and the industry in the grip of an energy crisis, much of ATRP’s early research focused on demonstrating the use of alternative energy resources such as wood, solar, and methane gas.

One of the earliest demonstrations of solar heating of broiler houses

One of the first scalder covers to reduce heat loss and conserve energy

One of the earliest demonstrations of an anaerobic digester to convert poultry waste to biogas and stabilized sludge for environmentally friendly on-farm applications

One of the first USDA-approved sound-absorbing panels to reduce noise levels in processing plants

1980s – Systems Development Projects

During the 1980s, the program’s focus shifted from energy efficiency to environmental compliance, electronic automation technology, and plant maintenance practices.

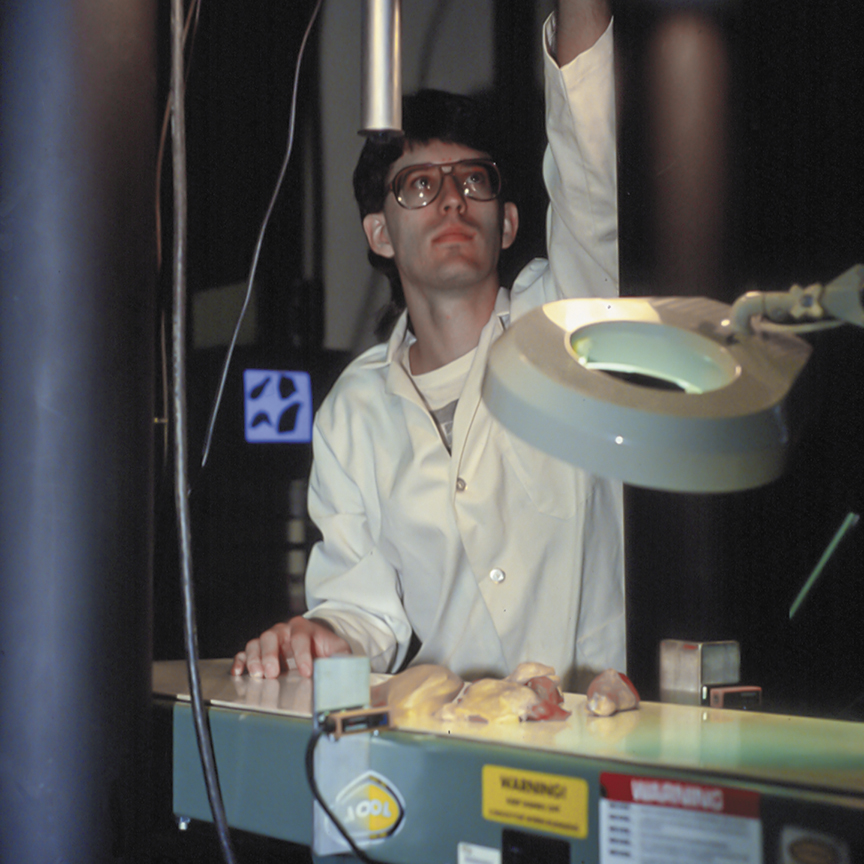

One of the first computer vision systems developed specifically to size and identify poultry parts

An ingenious thermally enhanced dewatering system for quickly and affordably removing more than half of the water in dissolved air flotation (DAF) skimmings

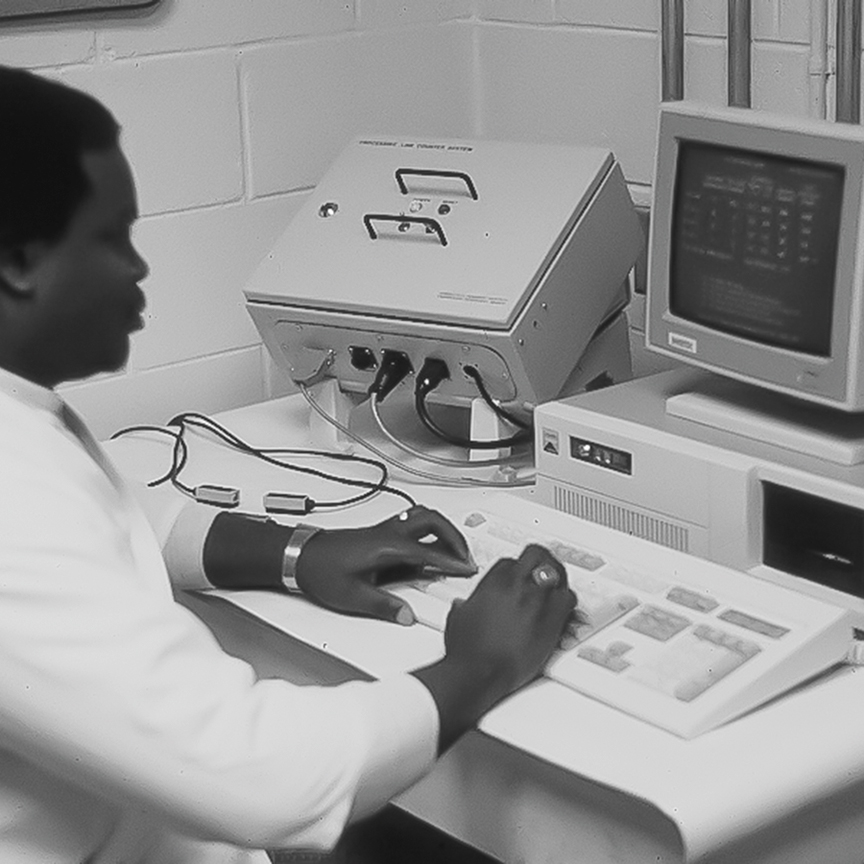

One of the first electronic bird-counting systems for providing real-time, continuous tracking of processing plant line speeds and capacity utilization

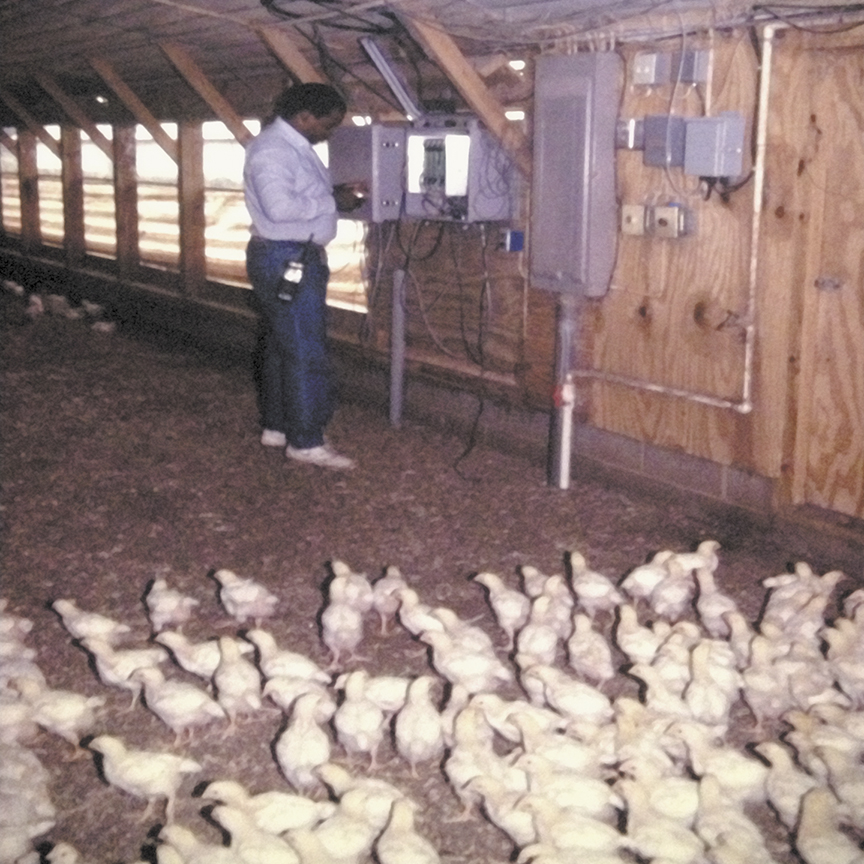

A state-of-the-art computerized broiler house management system for monitoring and controlling growout operations

One of the first computer systems designed for real-time data collection from the processing plant floor

Golden Nugget

In 1984, ATRP initiated a Workshop on Safety in the Poultry Industry in conjunction with the National Chicken Council, National Turkey Federation, and Georgia Poultry Federation. Today, this annual event has become the industry’s only National Safety Conference and is co-hosted with the U.S. Poultry & Egg Association. Each year, hundreds of safety professionals from across the United States attend the three-day conference, which provides a national forum for information transfer on safety management in the poultry industry.

1990s – Applied Research Projects

During the 1990s, ATRP focused on five primary research areas: environmental sustainability, ergonomics and worker safety, food safety, factory automation, and computer information systems.

One of the first computer vision systems developed specifically for poultry quality and defect screening

One of the first wearable computer systems designed for data collection and transfer in processing operations

One of the first biosensors developed for continuous on-line screening of pathogens in processing operations

An innovative ergonomic work assessment system to help reduce repetitive motion injuries in poultry processing workers

One of the first low-cost robotic systems to place poultry trays into shipping cartons

An innovative UV disinfection system for treating meat processing brines and chiller water

Golden Nugget

In 1995, ATRP designed and built the first Poultry World exhibit at the Georgia National Fair. Conceived by Fair leaders and the Georgia Poultry Federation, the exhibit is annually staffed by more than 100 industry and academic volunteers, and shares information with the public about all aspects of the poultry industry — Georgia’s #1 agricultural and agribusiness sector. Poultry World won an international award for “Outstanding Special Event” in its first appearance at the fair in 1995.

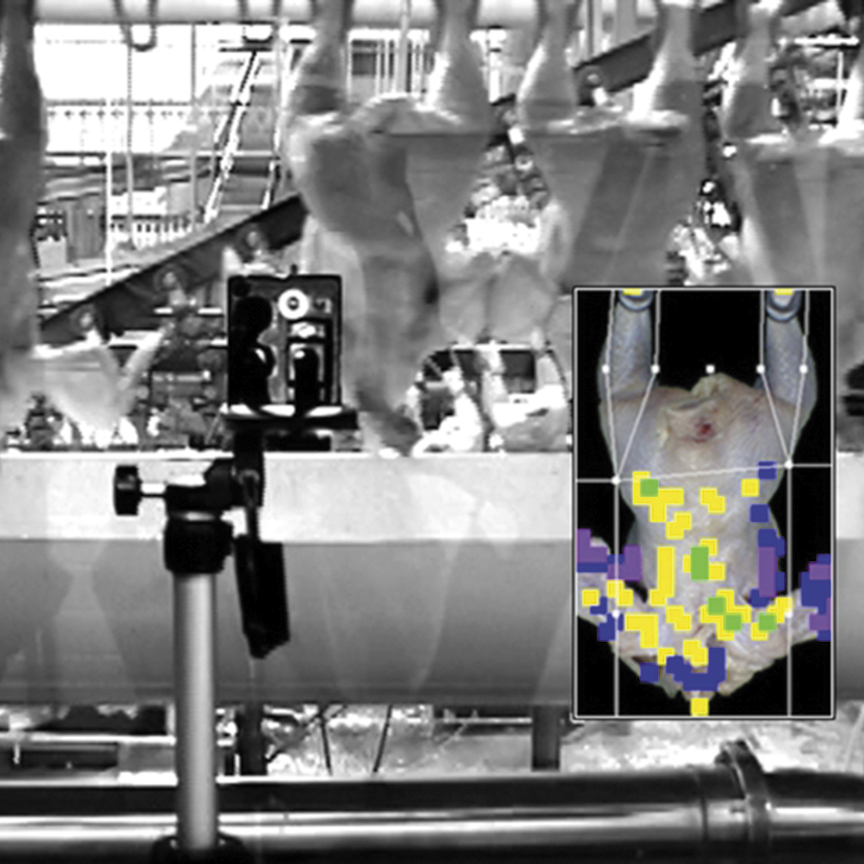

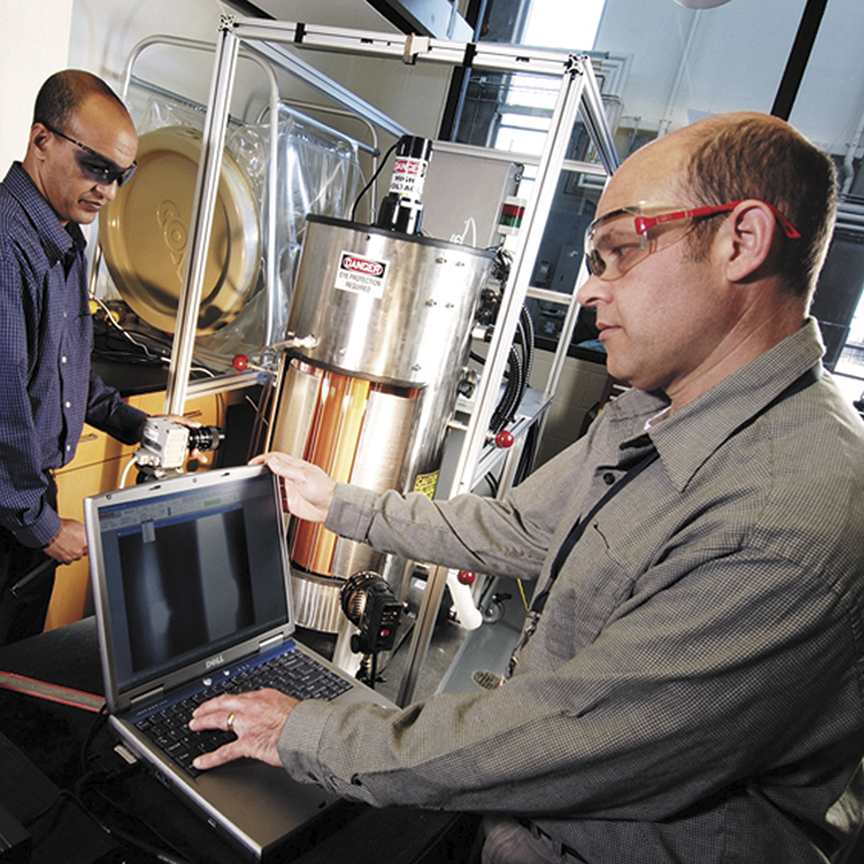

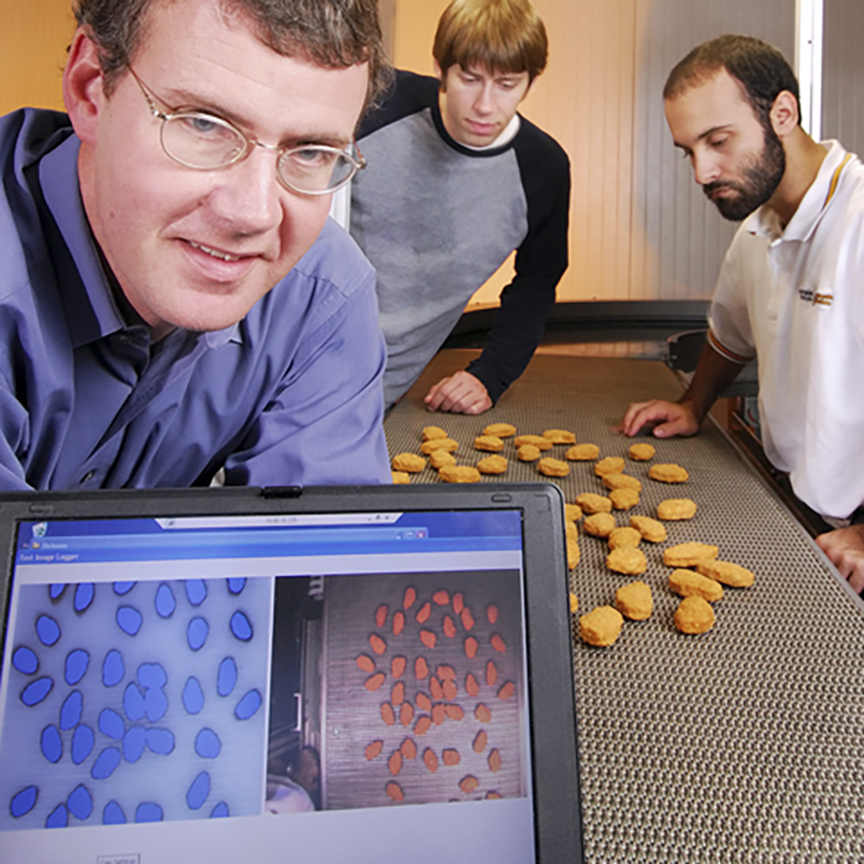

2000s – Computer Vision and Automation

In the 2000s, the program’s research focused on the development of machine vision and automation systems for screening of whole birds and portions for quality inspection and sorting.

An innovative automatic tray packing robot designed to withstand high-pressure washdown

One of the earliest demonstrations of a computer vision system for on-line screening and sorting of individual meat and poultry portions

One of the first computer vision systems for whole carcass automated grading

An infrared computer vision system for measuring temperature in various cooked meat products

Golden Nugget

In 2002, Meat & Poultry magazine ranked ATRP as one of the Top 10 programs in the United States serving the meat and poultry industry, noting…

“ATRP has a history of developing innovative poultry processing technologies, and successfully taking them from the drawing board to commercial applications.”

Golden Nugget

In 2005, ATRP moved into its new headquarters, the Food Processing Technology Building at Georgia Tech. The $9.4 million facility is the first of its kind at the university and serves as a cornerstone for multi-disciplinary research and development that creates innovative new technological designs, fosters active industrial and academic collaboration, and attracts technology firms interested in bringing new solutions to the challenges facing the food processing industry.

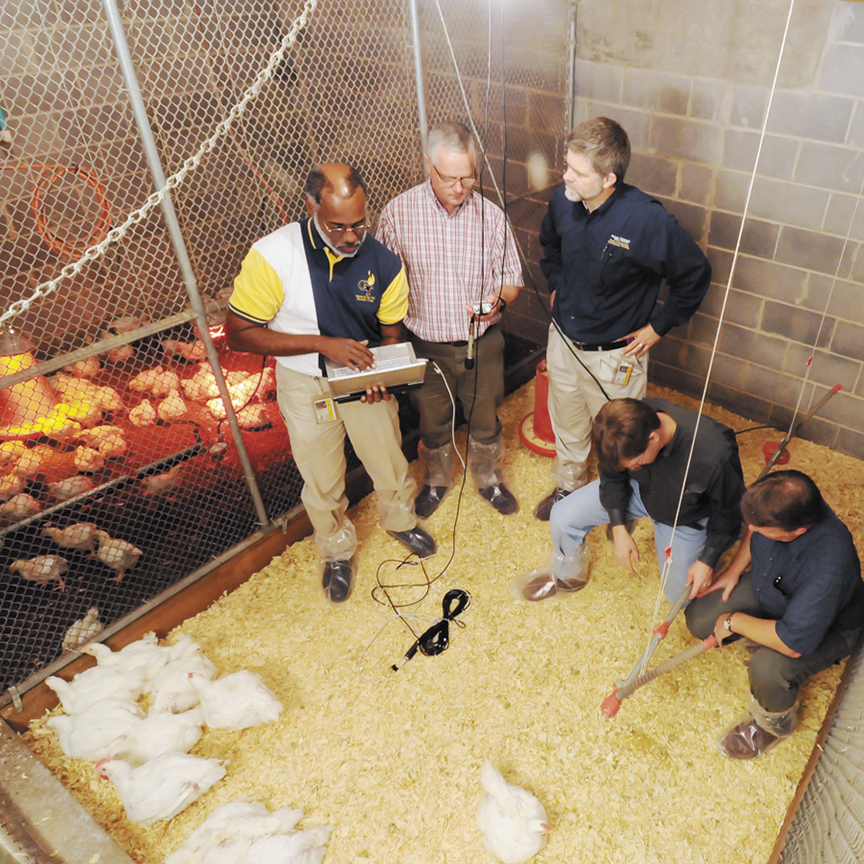

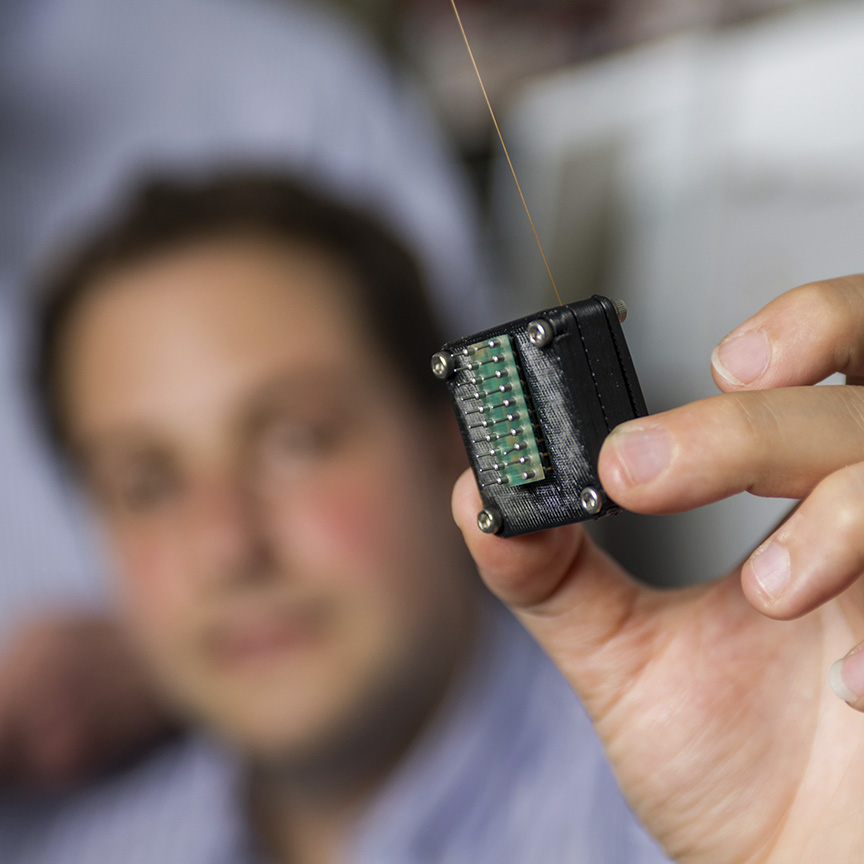

2010s – Advanced Sensing and Environmental Technology

During the 2010s, ATRP developed systems that incorporated advanced image and audio-based sensing for assessment of yield in manual deboning and the monitoring of live birds in growout houses. Environmental technologies included novel dynamic filtration for removing fats and proteins and magnetic nanoparticles (MNPs) for extracting nutrients from traditional wastewater streams.

An automated vision-based system that estimates yield loss by correlating image characteristics with the amount of meat remaining on a chicken frame after it has been deboned

An innovative automated system that records and analyzes the vocalizations of birds to evaluate their well-being during the growout cycle

A novel filtration system for water recycling and byproduct recovery in poultry processing operations

One of the first investigations of the use of magnetic nanoparticles to remove and recover phosphorus from poultry processing wastewater

A low-power electro-thermal gas sensor for real-time monitoring of ammonia levels in poultry houses that exhibits high selectively and fast response/recovery time

Golden Nugget

In April 2016, ATRP was honored to co-host the International Food Automation Networking (IFAN) Conference at the Georgia Tech Research Institute Conference Center, which was held for the first time ever in the United States. Professionals from food and allied industry sectors representing seven European countries, the United States, Canada, and Australia attended. The biennial event founded and co-hosted by BMC, United Kingdom, focuses on automation and technology R&D challenges/opportunities for creating the food processing system of the future.

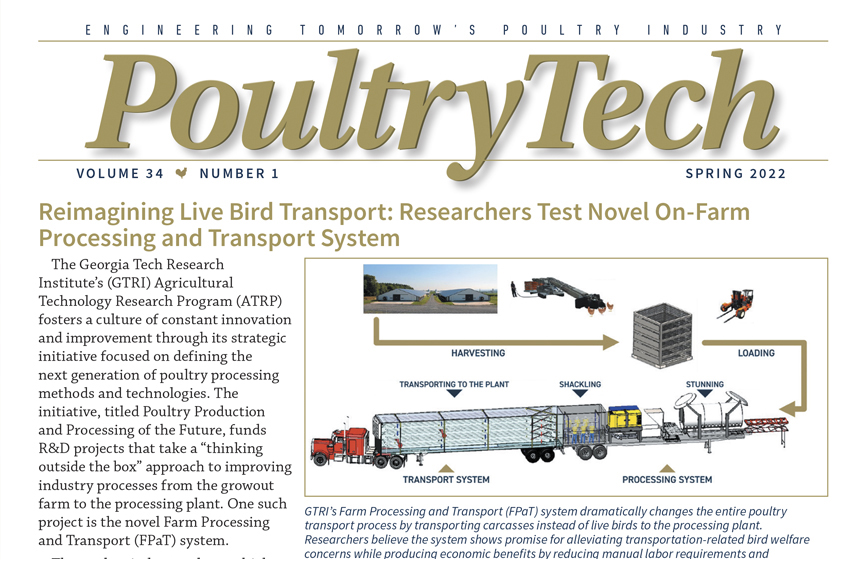

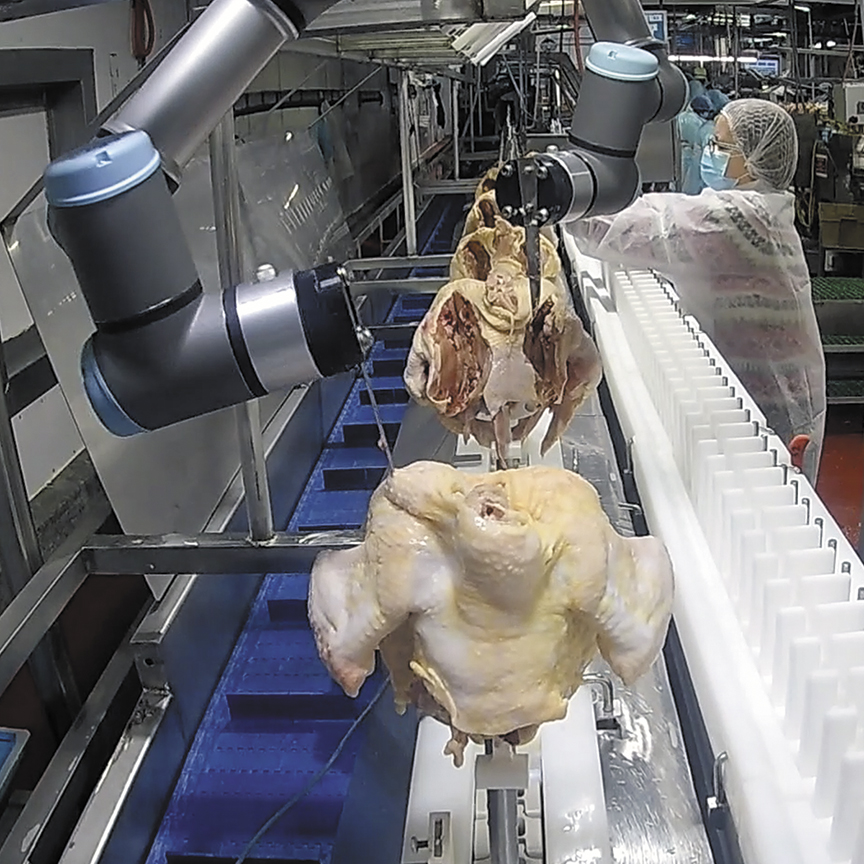

2020s – Industry 4.0

Today’s ATRP projects are seeking to fundamentally rethink certain aspects of the poultry continuum and how new technologies and concepts might drive transformational innovation into the industry. Areas of focus include thermal processing, advanced sensing, and processing and growout robotics.

An automated robotic cutting system for performing bird shoulder cuts on a moving poultry deboning cone line

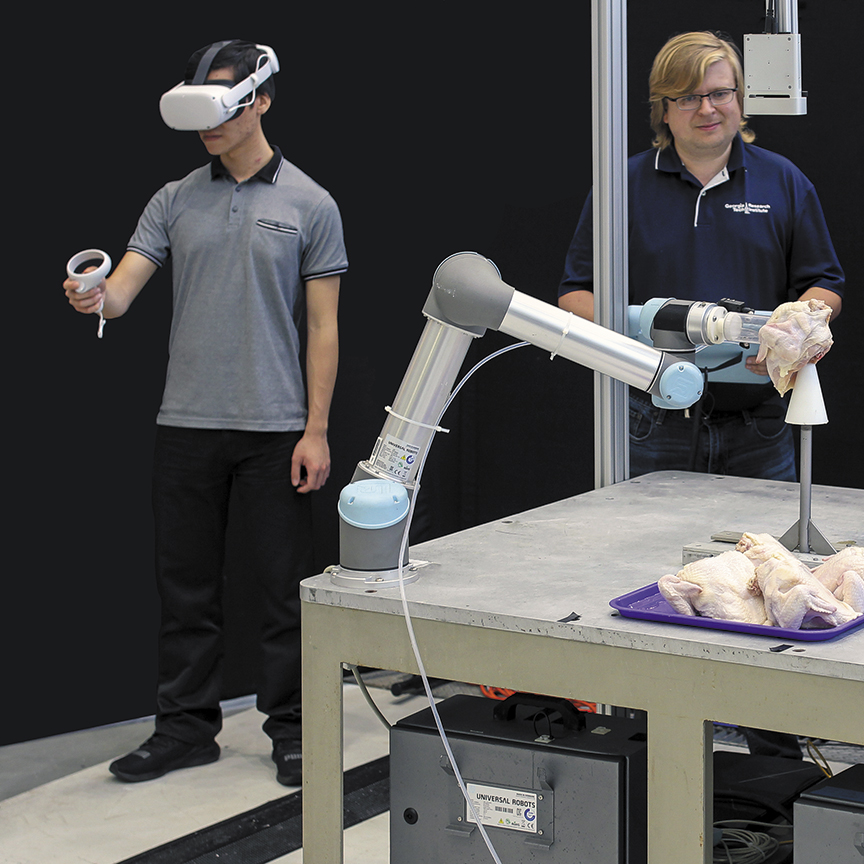

An exploration of virtual reality (VR) systems for aiding the development and deployment of robotic systems in processing environments

A fully autonomous ground robot for performing broiler and broiler-breeder rearing and management tasks in growout houses

An innovative in-line immersive chilling system that uses ice slurry as an alternative chiller medium

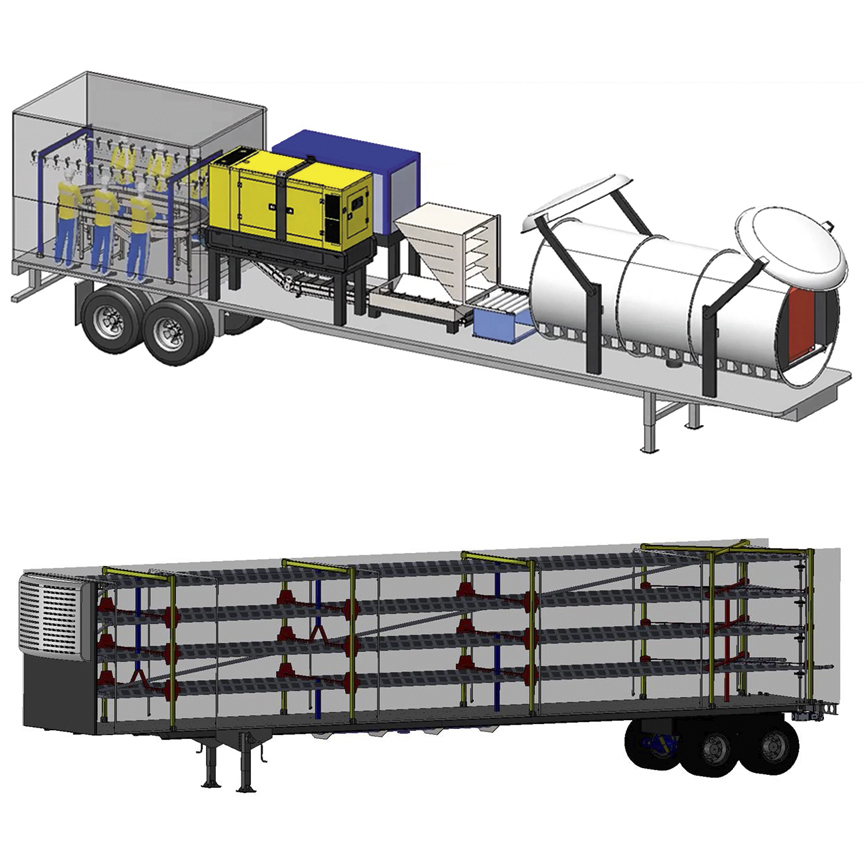

A novel farm processing and transport system that transports carcasses instead of live birds to the processing plant, alleviating transportation-related bird welfare concerns

Golden Nugget

2023 marks ATRP's 50th Anniversary!