Robotics/automation research studies focus on “intelligent” automation systems, which incorporate advanced sensors, robotics, and computer simulation and control technologies in an integrated package.

Automated Cone Loading

Researchers with the Georgia Tech Research Institute’s (GTRI) Agricultural Technology Research Program are exploring the use of collaborative robots for materials handling tasks in poultry processing plants. Also known as cobots, these robots are designed to work safely alongside humans in any number of tasks. The GTRI team has constructed a robotic test bed centered on the Baxter robot by Rethink Robotics. Baxter is learning to pick and place chicken front halves (carcasses without legs and thighs) on cones for deboning during further processing. The project is one of many underway aimed at demonstrating the next generation of poultry processing.

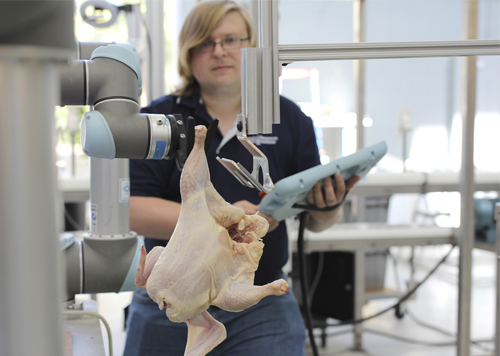

Intelligent Cutting and Deboning System

The Intelligent Cutting and Deboning System uses 3D imaging and a robotic cutting arm to sever the tendons and joints on bird front halves in preparation for the removal of the wings and breast meat, also known as a butterfly cut. The objective is to make cuts that maximize yield while eliminating bone chips in the cut meat. Because it combines advanced robotics, image processing, and statistical modeling in one device, the system can think and react to its environment just like a human — only it can do it better and faster. This makes it particularly unique compared to other fixed automation systems.

Growout Robotic Testing

Poultry houses require daily monitoring to ensure animal health and proper house operation. Many poultry farmers find this labor intensive and time consuming. To address this challenge, ATRP researchers along with colleagues at the University of Georgia have developed a prototype mobile robot system for operation in confined poultry houses.